Our Products

MSPL Standing Seam Roof Panel

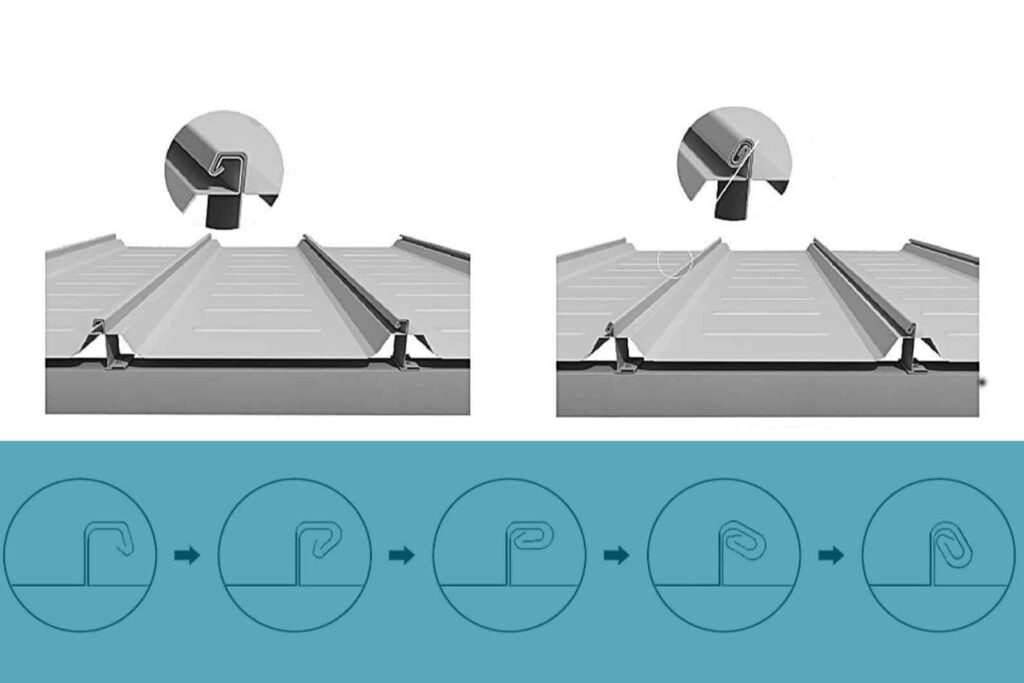

For the most demanding application MSPL offer Standing Seam roof panel. This high performance roof system boasts the highest wind up lift resistance. A unique one piece GI clip design allows for unlimited thermal movement. Side joints are double lock-seamed to ensure weather tightness. This workhorse panel is factory or field formed to yield continuous long length panels.

We work with clients to integrate the flow of the customer experience across channels (e.g., face-to-face, telephone), opening up new lead sources, supporting sales for smaller-value transactions,and creating new models for service. We continuously provide new and practical perspectives on the evolving. Customer Decision Journey, and work with clients to make the deep, transformational changes needed to support new strategies and capability demands. Earn more interest and get flexible access to your savings.

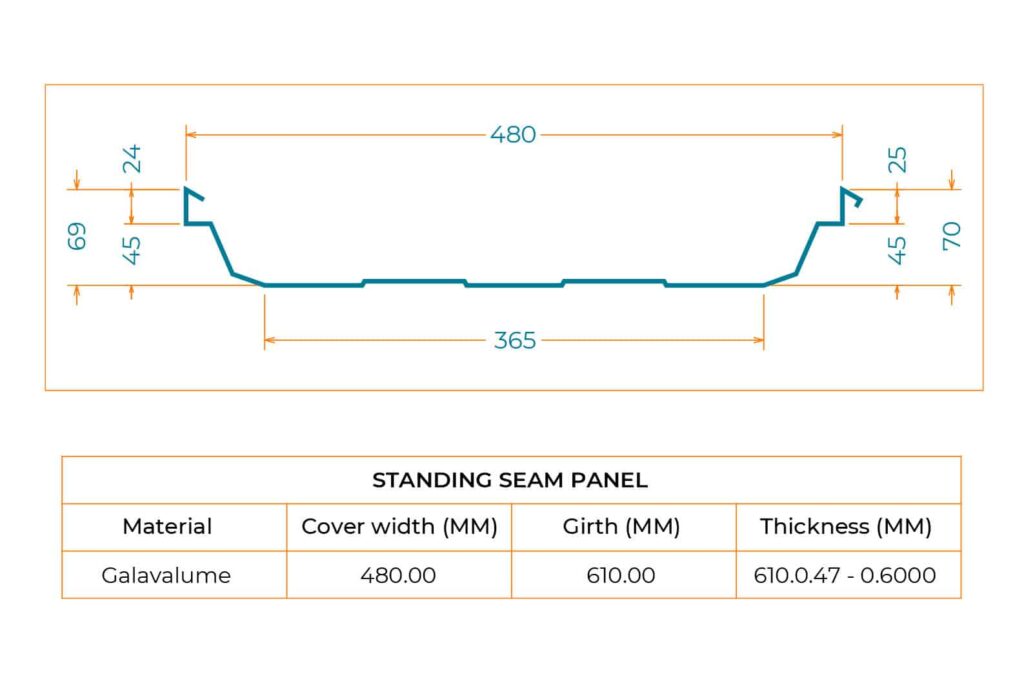

Technical Data

- ASTM A 653- Standard specification for steel sheet, Zinc coated (Galvanized) or Zinc- aluminium alloy coated (Galvalume), Pre painted, Bare (un painted).

- Thickness: 0.47mm to 0.8mm

- Panel coverage: 460mm

- Attachment: Concealed clip for thermal movement

Features & Benefits

- Designed to cope with the forces of expansion and contraction. This is accomplished by allowing the panels to freely move up and down the roof slope.

- Sliding clips allow thermal movement on a wide variety of building widths.

- Field seamed, hidden fasteners joinery provides maximum protection against the elements.

- The additional small rib design provides added strength against potential foot traffic damage

On-Site Roll-Forming

MSPL Standing Seam sheet can be manufactured at site using world-class mobile roll-forming technology, which not only gives single length sheet from the ridge of the roof to the eave, but also helps to make it a leak-proof structure with better control over quality installation.